our Services

your

benefit

FROSIO competence

- Inspection of surface preparation on steel structures and seagoing vessels

- Monitoring of coating application

- Inspection of ballast water tanks and preparation of CTF (Coating Technical File) acc. to IMO PSPC

- Quality control and final inspections of the coating work

- Topcoat inspections on mega yachts

- Advice on planning of infrastructural requirements for painting, such as temperature / humidity control or air extraction

5 years of relevant experience are required to achieve FROSIO level 3

FROSIO competence

- Inspection of surface preparation on steel structures and seagoing vessels

- Monitoring of coating application

- Inspection of ballast water tanks and preparation of CTF (Coating Technical File) acc. to IMO PSPC

- Quality control and final inspections of the coating work

- Topcoat inspections on mega yachts

- Advice on planning of infrastructural requirements for painting, such as temperature / humidity control or air extraction

5 years of relevant experience are required to achieve FROSIO level 3

Industry Focused Services

Topcoat inspections on mega yachts

High gloss areas on mega yachts require a lot of experience in managing all related matters. From design to surface preparation to filler application, every detail is important to get the best topcoat appearance. We are ready for the task.

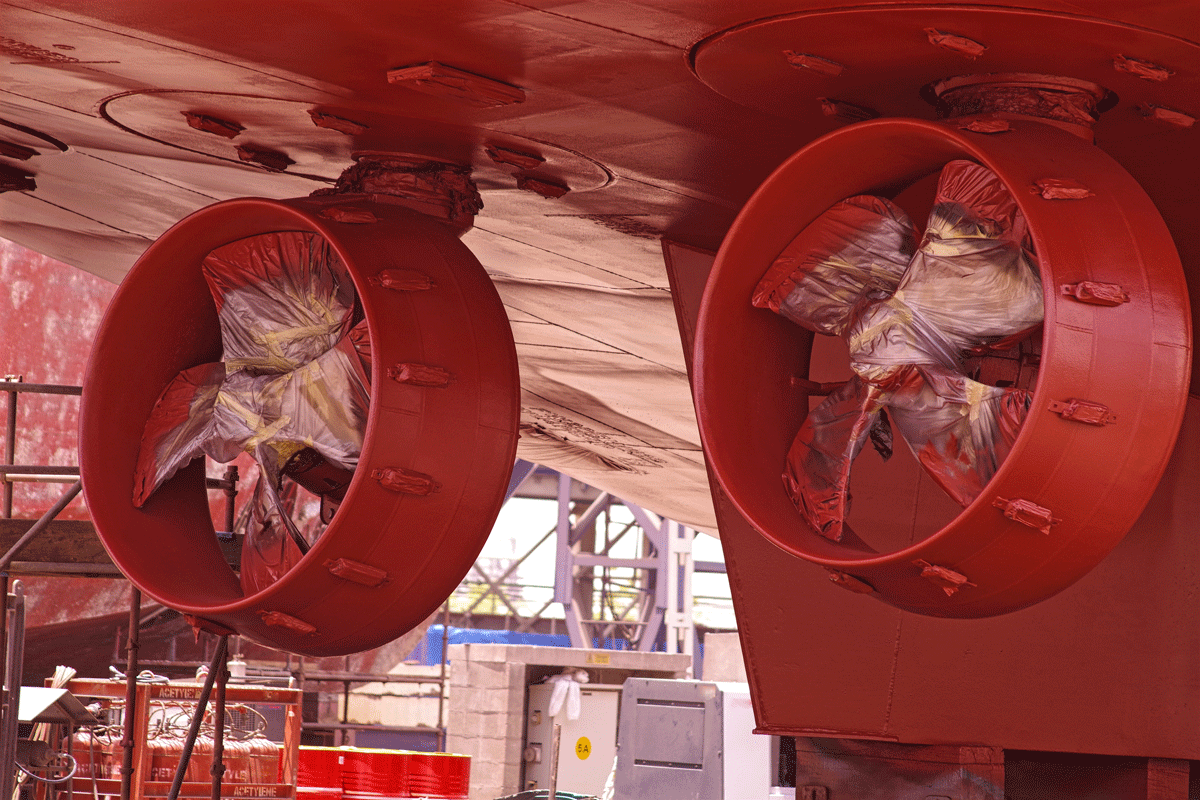

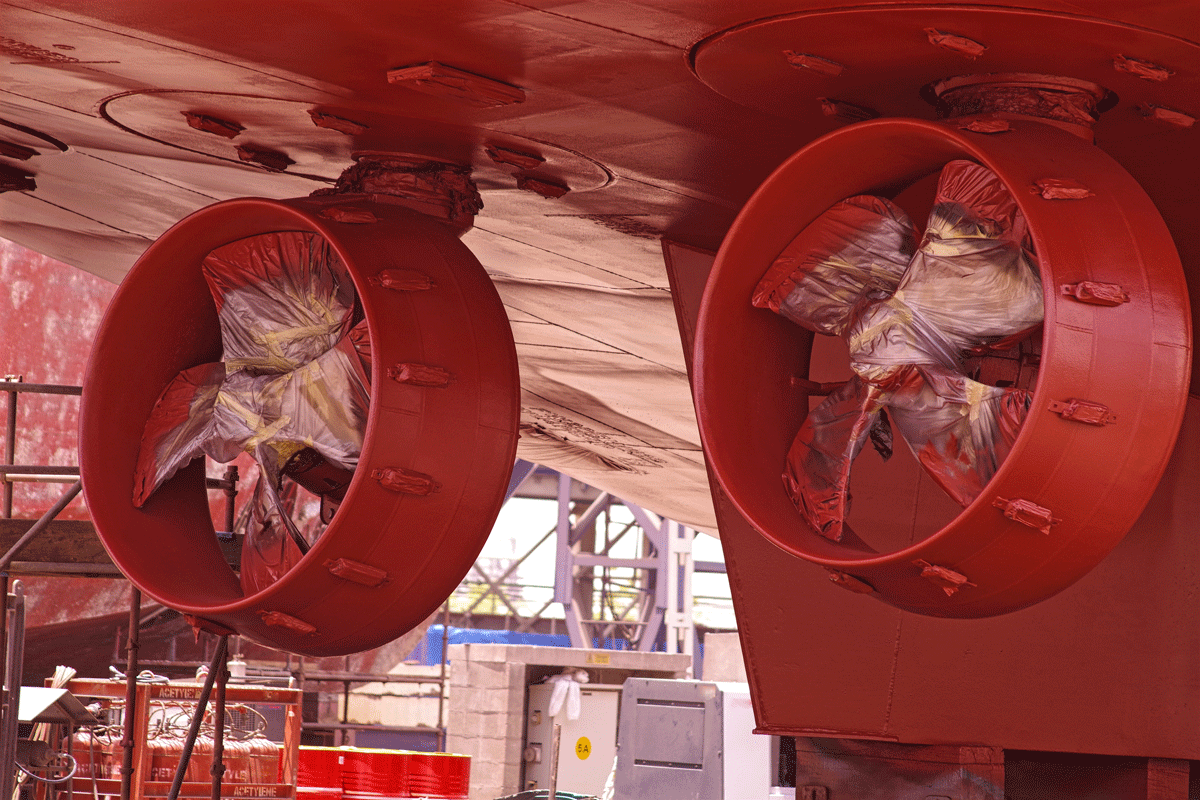

Monitoring of surface preparation on steel structures and coating application

Steel protection against corrosion starts with surface preparation. We monitor every step from surface preparation through to the application of every layer of paint. With this quality control best possible results are achieved.

Rope access inspections

As certified FISAT rope technicians we are qualified to, wherever possible, carry out pre- or final inspections via rope access if no scaffolding is onsite. This can be a time and budget saver.

Project Management

With Level 3 FROSIO certified Inspectors and years of experience in maritime industries, we know what it takes to finish a project in time.

Advice on planning of infrastructural requirements for topcoat application

Infrastructural solutions such as air exchange rate, temperature / humidity control or extraction for topcoat application, require experience. We can help to find the best quality solution for your project.

Ballast water tanks

Ballast water tanks on seagoing vessels are critical areas in terms of corrosion. Therefore, the International Maritime Organization (IMO) has adopted performance standards for protective coatings (PSPC). FROSIO level 3 inspections are necessary to get your documentation approved.

>> Read more about PSPC / >> PSPC Code

>> Read more about corrosion protection of ballast water tanks

Engineering

As qualified solidworks and autodesk inventor users, we bring in years of experience as 3D design engineers.

Quality Management

Experience in medical vet. supply and naval industries has given us a clear view of what is necessary to find the best balance between high quality and precise project time scheduling.